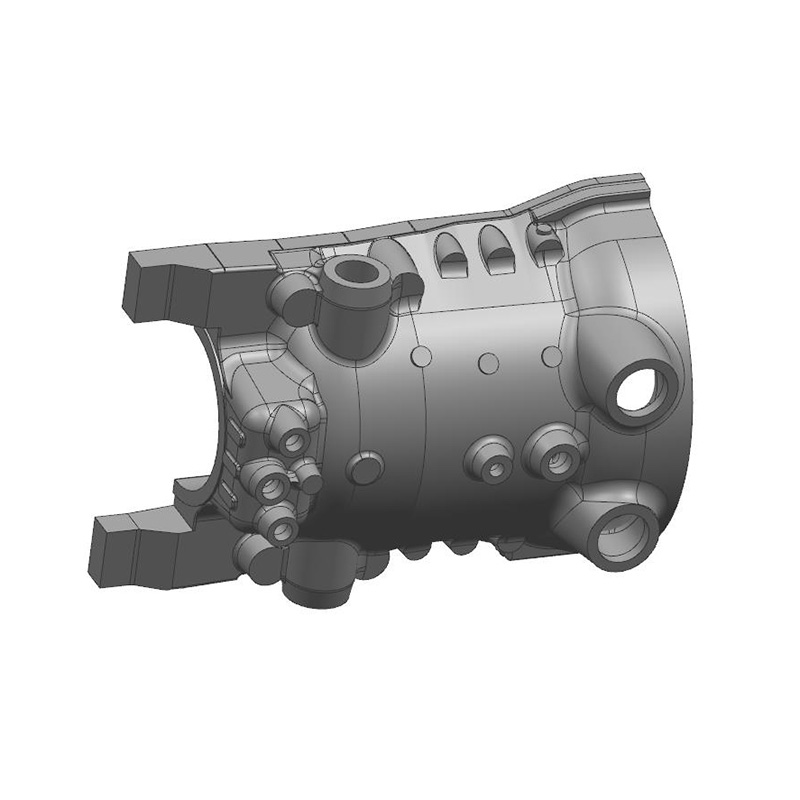

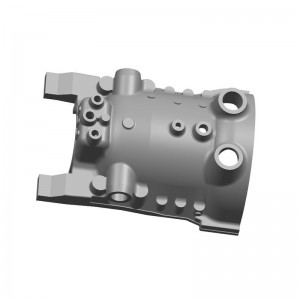

Large Cast Steel Steam Turbine Cylinder Body for Power Generation

Detailed Description

Production Process:

Resin sand casting process

Production Capacity:

Casting/ Melting/ Pouring/ Heat Treatment/ Rough Machining/ Welding/ NDT Inspection (UT MT PT RT VT)/ Packaging/ Shipping

Quality Documents:

Size report.

Physical and chemical performance report (including: chemical composition/tensile Strength/yield strength/elongation/reduction of area/impact energy).

NDT test report (including: UT MT PT RT VT)

Advantage

Introducing our large cast steel steam turbine blocks for power generation. With our state-of-the-art production facilities and processes, we are able to ensure unrivaled quality in every aspect of the production of this large and important component.

Our manufacturing capabilities include casting, melting, pouring, heat treating, rough machining, welding, non-destructive testing using ultrasonic, magnetic particle, liquid penetrant, radiography and visual inspection techniques, as well as packaging and shipping to ensure safe handling and delivery.

To ensure the highest quality products, we provide detailed quality documents, including dimensional reports, physical and chemical performance reports and non-destructive testing reports. Physical and chemical performance reports include rigorous testing of chemical composition, tensile strength, yield strength, elongation, reduction of area, and impact energy. Comprehensive NDT reports covering ultrasonic, magnetic particle, liquid penetrant, radiography and visual inspection techniques.

Our large cast steel steam turbine blocks for power generation are an integral part of power generation facilities and our commitment to quality ensures our customers can rely on the performance and longevity of our products. Our expertise, experience and strict quality control measures ensure that our products are reliable, efficient and cost-effective.

FAQ

1. What are your prices?

Our prices are subject to change depending on the casting material and property and other market factors. Certainly, factory price and high quality is guarantee. We will share you an updated price list after your company contact us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Quality documents, Insurance; Original of certification, and other export documents where required.

4. What is the average lead time?

Generally is 2-3 months.

5. What kinds of payment methods do you accept?

You can make the payment to our bank account by TT/ LC: 30% deposit in advance, 70% balance against the copy of B/L.