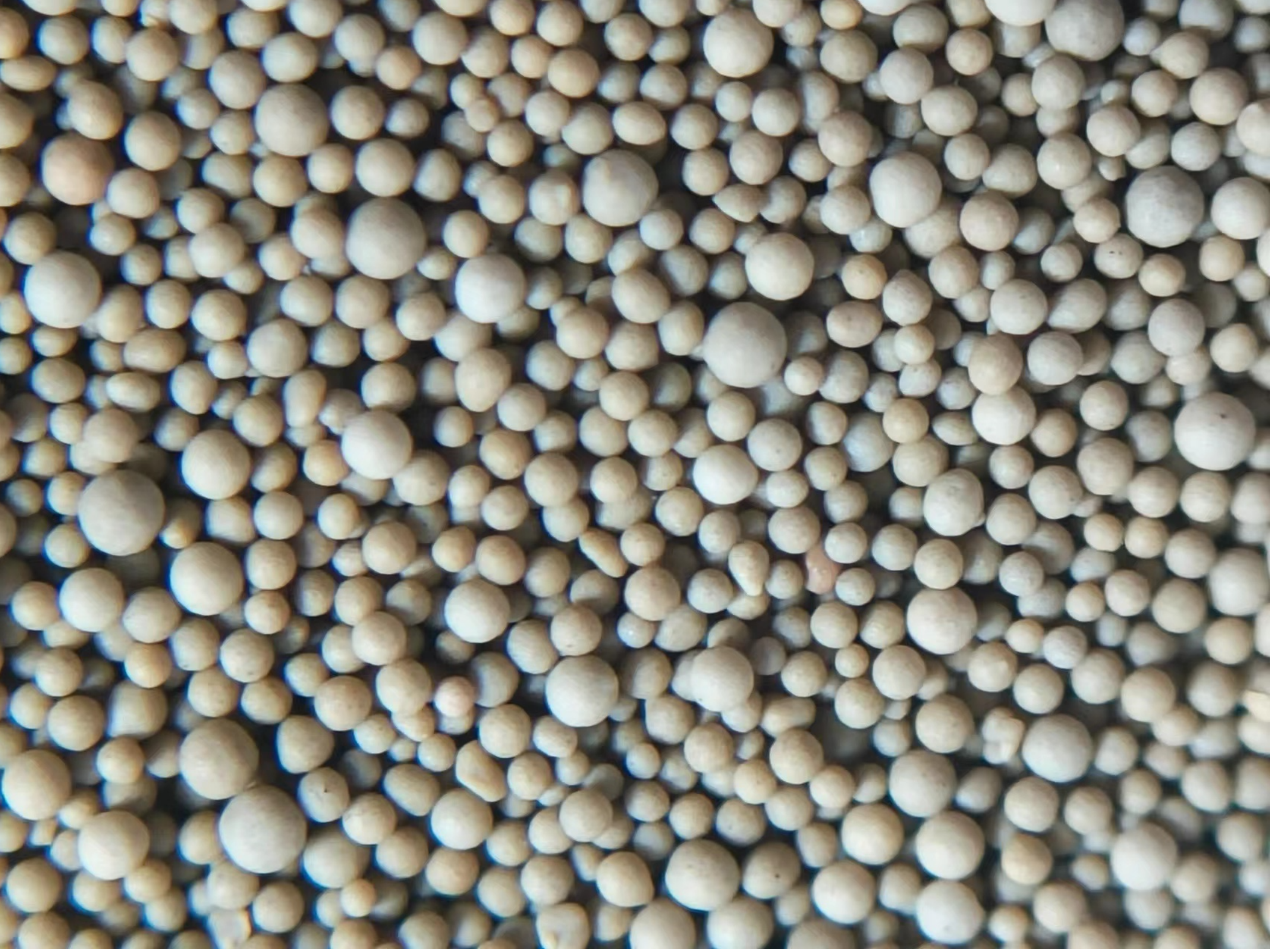

According to calculations and statistics, the ceramic sand shell casting process requires an average of 0.6-1 tons of coated sand (core) to produce 1 ton of castings. In this way, the treatment of used sand has become the most critical link in this process. This is not only the need to reduce manufacturing costs and improve economic benefits, but also the need to reduce waste emissions, realize circular economy, live in harmony with the environment, and achieve sustainable development.

The purpose of reclamation of coated ceramic sand is to remove the residual resin film coated on the surface of the sand grains, and at the same time remove the residual metal and other impurities in the old sand. These residues seriously affect the strength and toughness of the coated ceramic sand reclaimed, and at the same time increase the amount of gas generation and the probability of producing waste products. The quality requirements for reclaimed sand are generally: loss on ignition (LOI) < 0.3% (or gas generation < 0.5ml/g), and the performance of reclaimed sand that meets this index after coating is not much different from new sand.

The coated sand uses thermoplastic phenolic resin as a binder, and its resin film is semi-tough. In theory, both thermal and mechanical methods can remove the residual resin film. Thermal regeneration utilizes the mechanism of carbonization of resin film at high temperature, which is the most sufficient and effective regeneration method.

Regarding the thermal reclamation process of coated ceramic sand, research institutes and some manufacturers have conducted a large number of experimental studies. At present, the following process tends to be used. The roasting furnace temperature is 700°C-750°C, and the sand temperature is 650°C-700°C. The reclamation process is generally:

(Vibration crushing) →magnetic separator →waste sand preheating → (bucket elevator) → (screw feeder) → reclaimed sand storage hopper →boiling fan →boiling cooling bed →dust removal system →core sand powder →hopper Lifting hoist →flue gas discharge →waste sand transportation →fluidized roasting furnace →intermediate sand bucket →coated sand production line

As far as ceramic sand reclamation equipment is concerned, thermal reclamation is generally used. Energy sources include electricity, gas, coal (coke), biomass fuel, etc., and heat exchange methods include contact type and airflow boiling type. In addition to some well-known large companies with more mature recycling equipment, many small companies also have many ingenious recycling equipment built by themselves.

Post time: Aug-08-2023